High refractive index, low birefringence, optical grade amorphous polyolefin.

APEL™

Cyclo Olefin Copolymer (COC)

Applications detail

Applications

Characteristics

- Introduction

- Characteristics

- Applications

APEL™, a cyclo olefin copolymer (COC) developed by Mitsui Chemicals using Ziegler polymerization technology, is available in resin form. The resulting material possesses a unique set of characteristics representing the best properties of polyolefins and amorphous plastics.

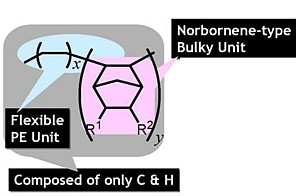

Distinguished by a high density, bulky structure, APEL is a norbornene-type composed only of C&H which is amorphous, optically isotropic and non polar.

The material possesses many characteristics inherent in polyolefins such as excellent electrical insulating properties and outstanding moisture resistance. In addition, it features good melt processability/flowability, good clarity and transparency, high glass transition temperature (Tg), exceptional moisture impermeability, impressive gas barrier qualities and excellent chemical and heat resistance.

Compared to other resins and engineering plastics, this Cyclo Olefin Copolymer has a lower birefringence and the highest refractive index (1.54) among commercialized COCs and other cyclo olefin polymers, making it ideal for use in high performance film, optical lens and packaging applications such as mobile phone and digital camera, shrink film and in pharmaceutical packaging such as blister packs.

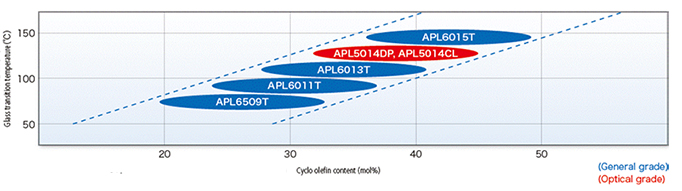

There are seven grades of APEL Cyclo Olefin Copolymer available with strong transparency, water vapor barrier and heat distortion resistance. Five of the grades are available for general purpose applications and lower Tg grades are suitable for film extrusion. Two grades are suitable for optical applications and injection molding applications. All grades exhibit good thermal, dielectric and electrical behavior, low shrinkage and low moisture absorption.

Apel Grades

Related Products

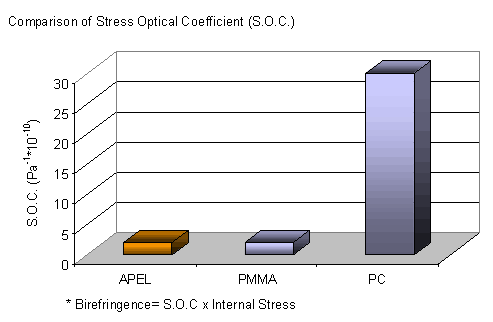

Low Birefringence

APEL™ Cyclo Olefin Copolymer's light transmittance of 91%, and low birefringence make it ideal for use in the development of opto-electric applications. As the table below illustrates, its birefringence is further superior to PMMA - less than 5 nm.

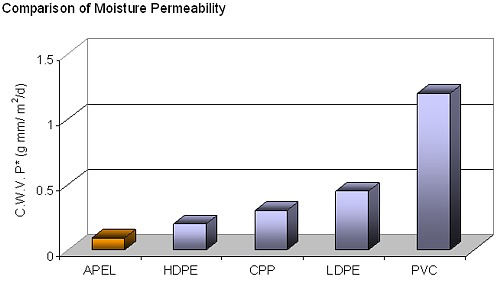

Low Moisture Permeability

APEL can be used to develop moisture barrier container and film applications due to its low permeability to water vapor and excellent humidity resistance. Its low moisture absorption prevents swelling and excellent moisture barrier to avoid evaporation of substrates.

As illustrated by the chart below, APEL Cyclo Olefin Copolymer has the lowest moisture permeability relative to other transparent resins.

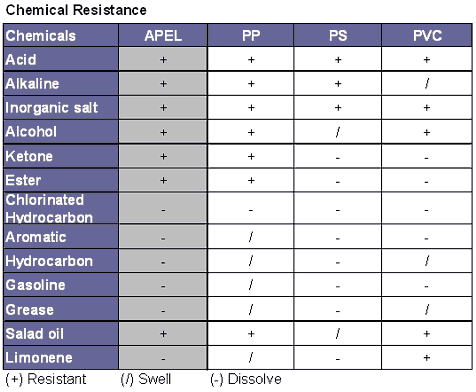

Chemical Resistance

In addition to excellent moisture impermeability, the Cyclo Olefin Copolymer displays an ability to resist acid, alkalis and alcohol among others. See chart below for full details.

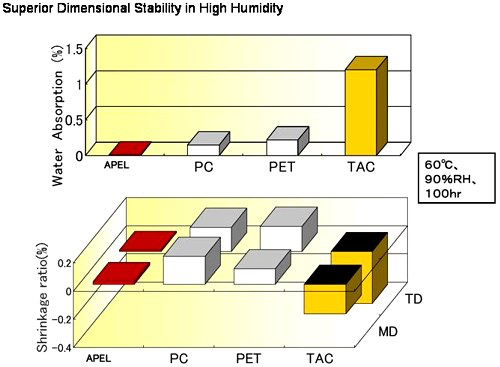

Dimensional Stability

APEL exhibits excellent dimensional stability, with low mold shrinkage and low coefficient of linear expansion.

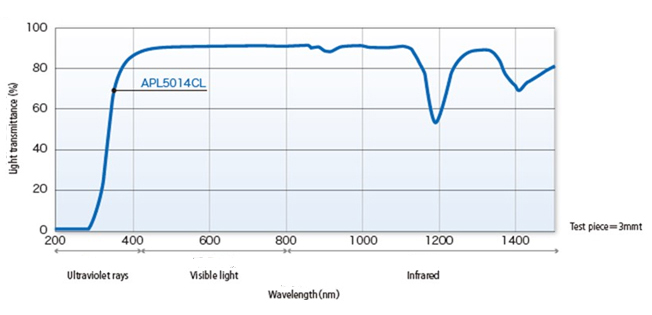

Transparency

APEL rates favorably relative to PMMA and PC with a light transmittance of 91%.

Light Transmittance

The following table provides insight into the complete parameters of all available grade classes including the physical, dielectric and optical properties of APEL™ Cyclo Olefin Copolymer.

There are numerous applications for APEL™ in the optical, film and packaging areas.

Optical

APEL has strong optical properties relative to other commercial resins and can be used in:

- Camera lenses (digital cameras and mobile phones)

- Lens for Head Mounted Display (AR, VR, MR)

- Automotive Camera Lens

- CCTV Lens

- Lens for sensor

- f θ lens for laser printer

- Pick-up lens for DVD player, recorder and SACD player

Packaging*

Packaging and multilayer barrier films produced with APEL Cyclo Olefin Copolymer should exhibit improved moisture and thermal resistance. Current and potential applications include:

- Pharmaceutical Packaging

- PTP Sheet (Blister Packaging)

- Shrink caps (Film type)

- Stand up pouches

- Food Packaging and Containers

- Easy cut film (Instant coffee small stick packaging film)

- Shrink film and label

- Kitchenware such as coffee maker cover

- Multilayer packaging

- Extrusion Coated Packaging