Resin modifiers of thermoplastics

TAFMER™

Polyolefin Elastomers

Low-crystallinity copolymer modifies polyethylene (PE) and polypropylene (PP) offering softness, improved impact resistance and lower melting point.

Applications detail

Applications

Characteristics

- Introduction

- Characteristics

- Applications

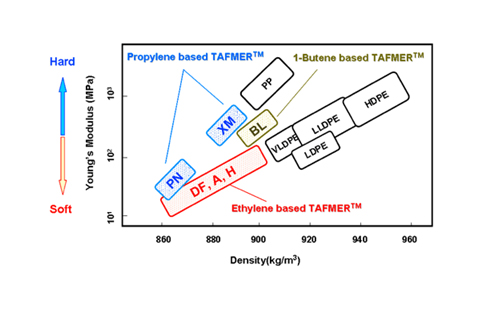

The TAFMER™ family of polyolefin elastomers is comprised of versatile copolymers that offer chemists and engineers more freedom to tailor polyethylene, polypropylene, EPDM, and polyamide compounds with unique properties. Owing to its low density, TAFMER™ is preferred by compounders who need to formulate the lowest cost solution for their customers. TAFMER™ is widely used in automotive thermoplastic polyolefin (TPO) compounds, wire & cable materials and packaging applications.

The polymer backbone of TAFMER™ is polyolefin based. Many grades are FDA compliant, and are supplied in talc-free form for immediate use in packaging film intended for food or aqueous containment. TAFMER™ is considered a most versatile polyolefin elastomer by formulators who are able to select the precise physical property balance they need, from a full menu of copolymers.

TAFMER™PN has superior elasticity when compared to ethylene based elastomers.

TAFMER™PN will not snap even when lifting a 500 gram weight in water boiling at 100℃.

TAFMER™PN does not whiten even when bent.

Related Products

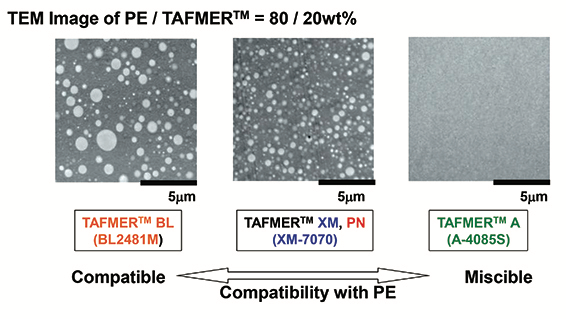

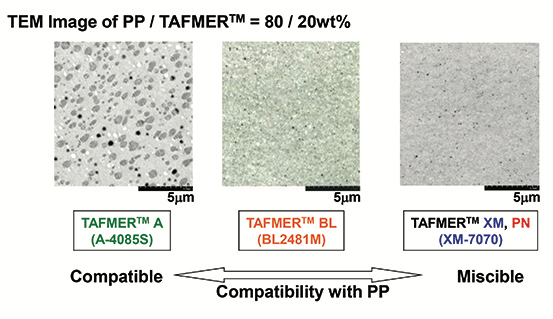

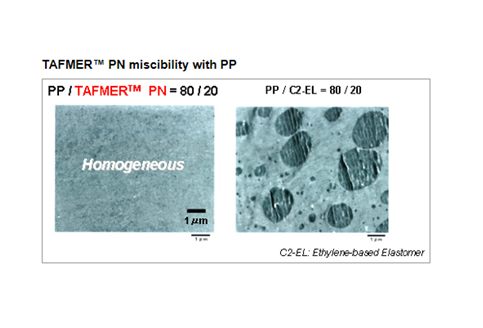

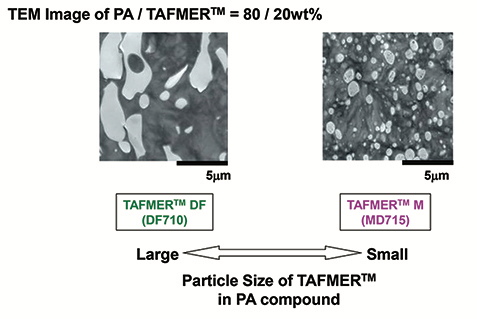

TAFMER™ polyolefin elastomer is a low-crystallinity alpha-olefin copolymer that features softness, low melting point, and compatibility with polyethylene (PE) and polypropylene (PP). When TAFMER™ is used to modify either PE or PP, the degree of compatibility may be selected to tailor the morphology of the compound. The resultant shift in physical properties is engineered to meet the requirements of the application.