Exfola™ is an additive for polyolefin, such as polyethylene and polypropylene, and combines the characteristics both of polyolefin and silicone.

Exfola™

Surface Modifier

Applications detail

Applications

Characteristics

- Introduction

- Characteristics

- Applications

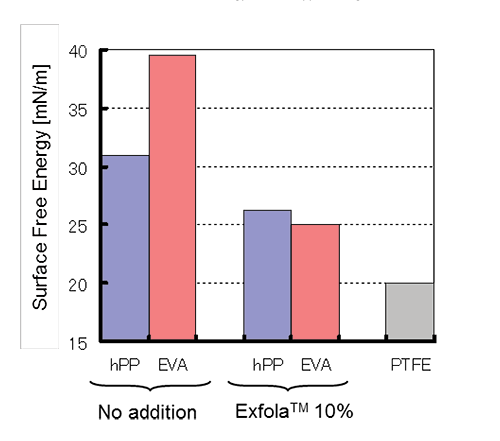

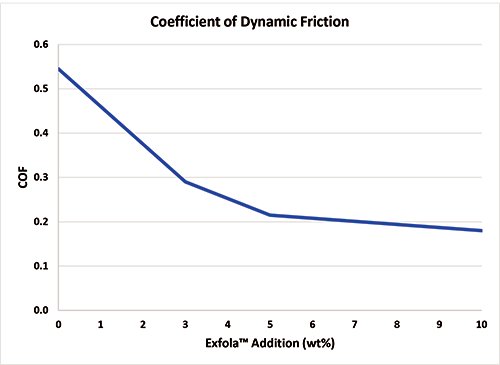

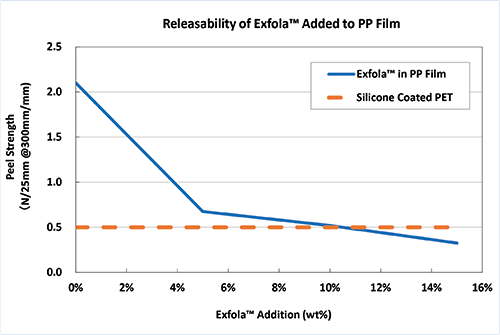

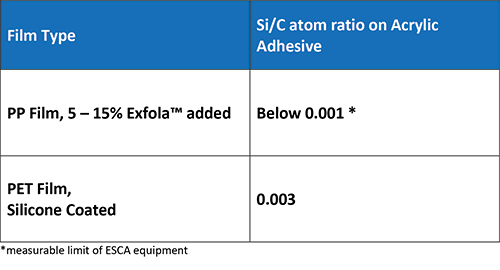

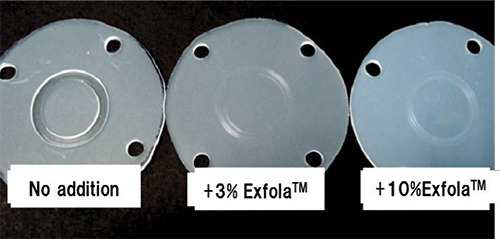

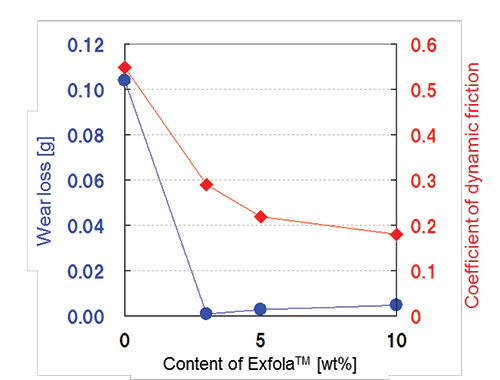

Exfola™ is an additive for polyolefin, such as polyethylene (PE) and polypropylene (PP), that combines the characteristics of polyolefin and silicone. Exfola™ is most often used as a surface modifier for injection molded parts, or extruded articles and film. Enhanced surface properties include:

- Releasability

- Water Repellency

- Oil Repellency

- Lower Coefficient of Friction

- Abrasion Resistance

- Surface Smoothness

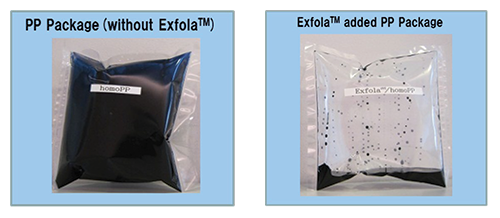

Exfola™ is widely used as a surface modifier of polyolefin film, sheet, containers, and packages. The product is available in pellet form, and in two types:

- Polyethylene-based (PE) Masterbatch

- Polypropylene-based (PP) Masterbatch

Related Products

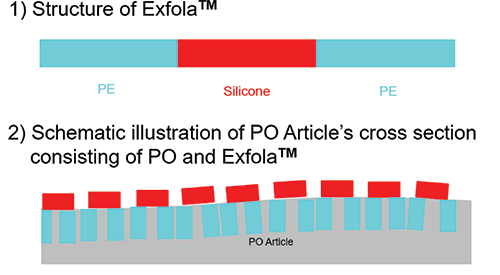

Exfola™ is a tri-block copolymer consisting of Silicones and polyethylene (PE) units. The pelletized product is opaque white in appearance, and offers very low specific gravity at 0.963 gm/ml. The polyethylene block allows Exfola™ to bond with polyolefins; polyethylene (PE), polypropylene (PP), polybutene (PB) and thermoplastic polyolefin (TPO) resins. The Silicone block modifies the surface properties of injection molded parts or extruded articles.

As a tri-block copolymer, Exfola™ demonstrates excellent compatibility with a polyolefin substrate due to its polyolefin block, while altering surface properties due to its Silicone block. These attributes create value in release film and flexible packaging applications, as well as industrial wear-resistant articles.