Solvent free and solvent based polyurethanes used in coatings, adhesives and laminations, for packaging, construction material and casting applications.

TAKELAC™/TAKENATE™ Polyurethane

Polyurethane

Applications detail

- Introduction

- Adhesives

- Coatings

Mitsui Chemicals supplies a variety of polyurethane materials from specialty Isocyanates XDI, H6XDI and their derivatives to polyurethane adhesives and dispersions. These products are used for coatings and adhesives where fast curing, flexibility, heat and chemical resistance are needed. There are solvent based, non-solvent and water based grades of TAKELAC™/TAKENATE™ used for different types of applications including:

- High performance adhesives for packaging and solar applications

- High performance water borne polyurethane dispersion (PUD) used in coating applications

- High performance specialty isocyanates for coating and ink applications

AndurElite™ (Fortimo™-1,4-H6XDI)

For aplications that require extra dynamic performance and abrasion resistance, the AndurElite™ prepolymer series is empowered by the next generation of ultra high-performance aliphatic diisocyanate (Fortimo™-1,4-H6XDI). It has a very linear and symmetrical structure with respect to the isocyanate groups, resulting in a highly crystalline hard-segment structure which provides ultra-high performance elastomer properties. Its "aliphatic" nature allows a light and color stable elastomer, which is exceptionally well suited for outdoor application or for applications in extreme environments.

Related Products

Mitsui Chemicals offers a line of high performance polyurethane adhesives for flexible packaging and solar applications.

Food Packaging

All Mitsui Chemicals’ polyurethane adhesives for flexible packaging are organo-tin compound free and bis-phenol A free. The adhesives are approved by FDA: FDA 21 CFR 175.105, FDA 21 CFR 177.1395 (for retort adhesive), and FDA 21 CFR 177.1390 (for retort adhesive).

TAKELAC is available as solvent based or solvent free. The solvent based adhesives feature three types which include the general performance type used in dry foods applications such as snack and coffee powder, the medium performance type used in applications such as juices and shampoos and the high performance type for boil and retort applications.

Mitsui Chemicals is the only company in the world that produces XDI (Xylene-diisocyanate). The XDI derivatives are categorized as aliphatic type because the material does not generate primary aromatic amines (PAA). Other benefits of XDI derivatives are organo-tin free, fast reaction time without the need for catalyst and good adhesion to metal.

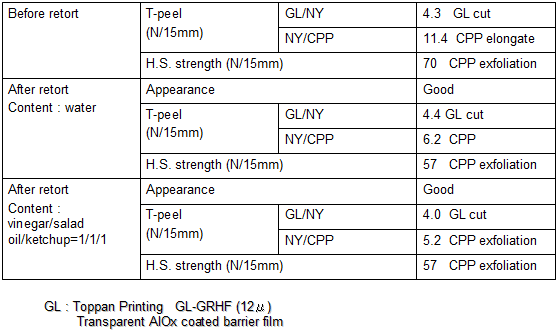

Properties

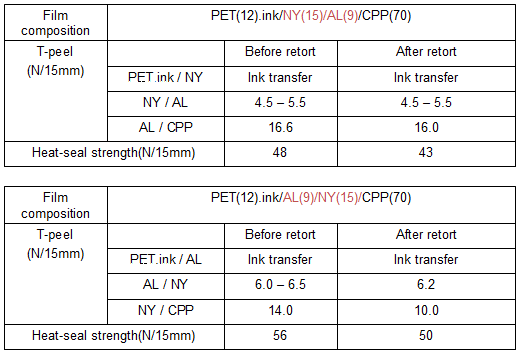

The TAKELAC grades are suitable for high retort packaging, handling temperatures ~135° C. They exhibit good adhesion performance for A1 structure (PET/AL/NY/CPP, PET/AL/CPP, PET/NY/AL/CPP, etc.) and for transparent film barrier (vmPET*/NY/CPP, etc.) (*VMPET: AIOx or SiOx coated transparent barrier film) The adhesives are suitable for holding content like - curry, meat, sauce, tuna, pickles, etc. and other similar food types.

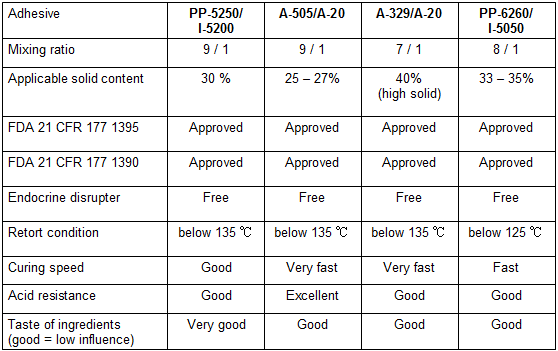

Comparison of aliphatic grade of TAKELAC™/TAKENATE™

Properties

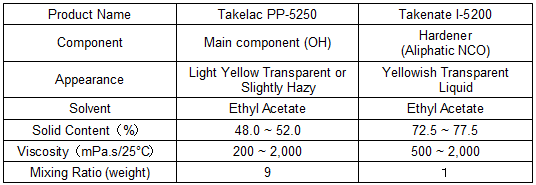

TAKELAC™ PP-5250/TAKENATE™ I-5200

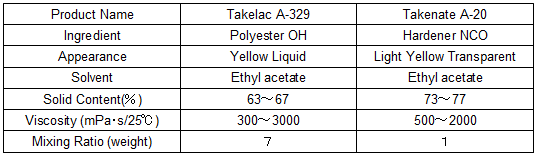

TAKELAC™ A-329 /TAKENATE™A-20

Evaluation-1

TAKELAC™ PP-5250/TAKENATE™ I-5200

Evaluation-2

TAKELAC™ A-329 / TAKENATE™A-20

Solar Applications

TAKELAC/TAKENATE, a 2 component type of adhesive, contributes to the reliability of the photovoltaic module due to properties that offer superior protection against the environment, such as:

- UV resistance

- Moisture barrier

- Superb adhesion and strength

- Excellent long term durability

- Resistance to weathering

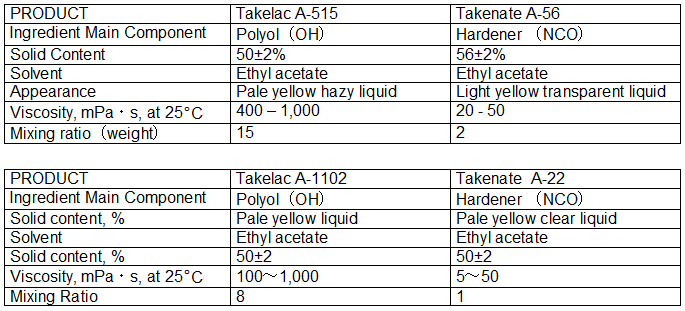

Mitsui Chemicals offers two product types: TAKELAC A-515/TAKENATE A-56, a standard grade and TAKELAC A-1102/TAKENATE A-22, a high performance adhesive offering exceptional stability under damp heat and freeze-thaw conditions.

TAKELAC™ A-515/TAKENATE™A-56

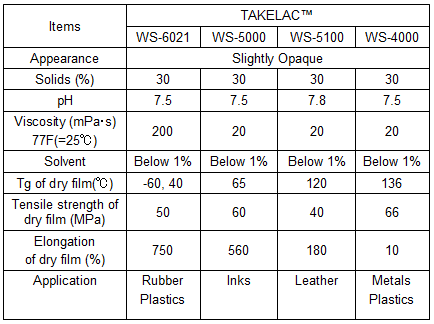

There are three series of TAKELAC™, high performance water borne polyurethane dispersion, used in coating applications. These include the WS Series, a self-cross linking polyurethane dispersion and the WPB series a gas barrier polyurethane dispersion. These PUDS are used in a variety of coating applications ranging from surface reinforcement, binders for water borne links, adhesive for film lamination to anti-corrosion coatings for metals.

TAKELAC™ WS-Series

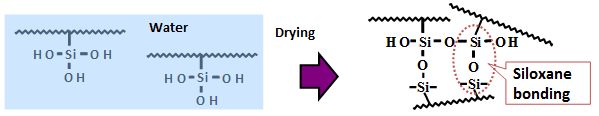

The WS series of TAKELAC is a polyurethane dispersion (PUD) with self-cross-linking technology that enhances coating properties, such as hardness, water and solvent resistance. The cross-linking finishing is achieved by the evaporation of water.

This series is used as a binder for water borne inks, adhesive for film lamination (PET, PC, PA, OPP), and surface reinforcement for coatings on leather, metal and plastics. It’s ideally suited for these applications because of its hardness, stain and heat resistance, high flexibility, adhesion to various films (PA, PET, OPP) and has good surface hydrolysis resistance.

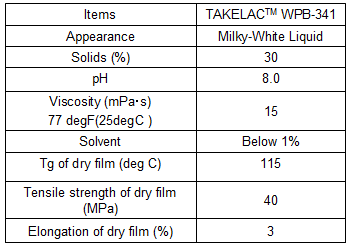

TAKELAC™ WPB-Series

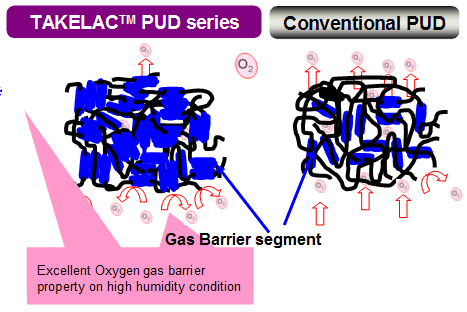

The WPB Series of TAKELAC is used in packaging and industrial films in addition to anti-corrosion coatings for metals.

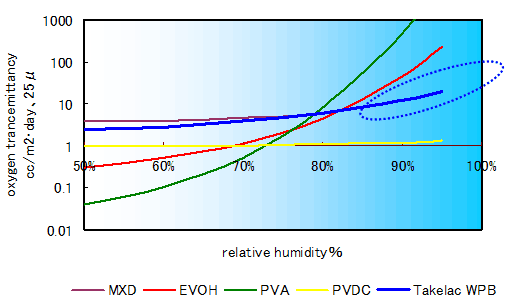

Oxygen barrier property / Humidity dependence

The series is a non-chorline based polymer with high flexibility and good adhesion to various films. The humidity dependence of the O2 barrier property is excellent in comparison with PVA and EVOH.

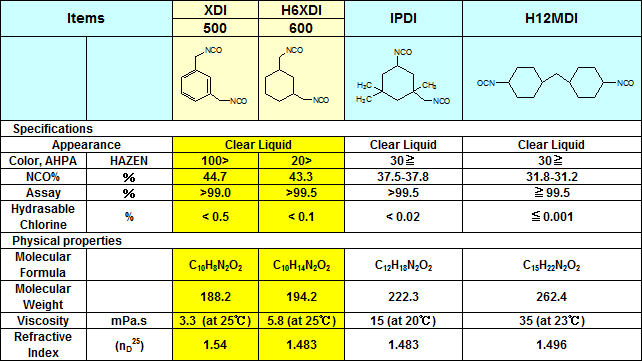

TAKENATE™ (Diisocynates, Polyurethane Curing Agent)

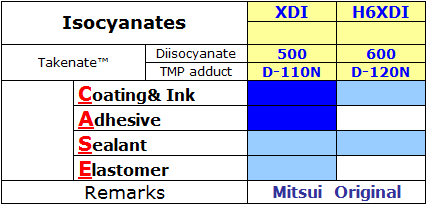

Mitsui Chemicals offers TAKENATE™, high performance specialty isocyanates:

- TAKENATE™ 500 (Xylylene Diisocyanate - XDI)

- TAKENATE™ 600 (Hydrogenated XDI - H6XDI)

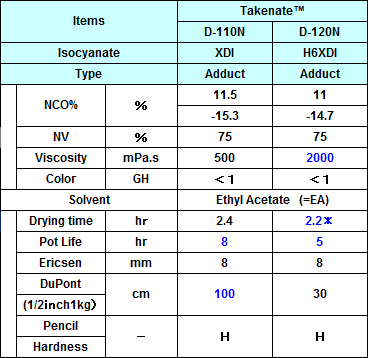

- TAKENATE™ D-110N (XDI adduct polymer)

- TAKENATE™ D-120N (H6XDI adduct polymer)

Properties

TAKENATE™ 500 and 600

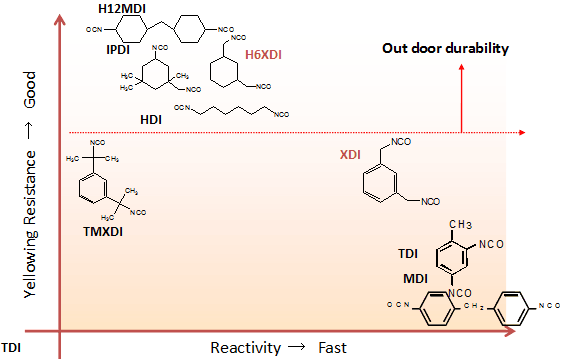

TAKENATE 500/TAKENATE D-110N have higher production efficiency than HDI, IPDI, better yellowing resistance than TDI and MDI, superior adhesion to a wide variety substrates, lower gas barrier, high reflective index and heat resistance. In the US, FDA sanction for use in food packaging adhesives under Non-Food Contact.

TAKENATE 600/TAKENATE 120N have numerous manufacturing and performance advantages including compatibility with various polyols, higher production efficiency than IPDI, excellent yellowing resistance and hardness, heat resistance and toughness better than HDI.

Comparison of Yellowing and Reactivity

Applications

The monomers, TAKENATE 500 and TAKENATE 600 are used in a variety of applications, such as raw materials for synthesis of resins for various CASE raw material and for PUD and UV Synthesis. Examples include PUD synthesis for metal and wood coating, coating resin synthesis for marine and wood coating and UV resin for 3C coatings.

TAKENATE D-110N and TAKENATE 120N are ideal for use as 2K curatives for coatings and ink applications. Application examples for TAKENATE™ D-110N include information and electronic appliances, automotive interiors and ink curatives. TAKENATE™ 120N is used in applications such as back sheet film for solar cell, automotive interiors and as an outdoor sealant.