Heat resistant, chemical resistant, modified polyamide "nylon" for electronic and automotive applications.

ARLEN™

Modified Polyamide 6T

Applications detail

Applications

Characteristics

- Introduction

- Applications

- Processing Methods

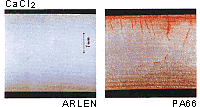

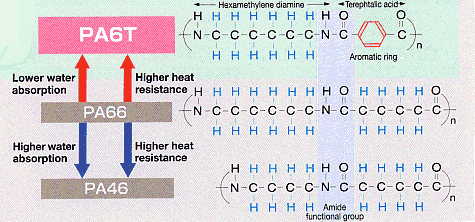

ARLEN™ is a heat resistant, modified polyamide 6T developed by Mitsui Chemicals, Inc. With a high melting point (320°C) and a rigidity level comparable to super engineering plastics, it possesses strong dimensional stability and chemical resistance. In addition, the effect of water absorption, which is a traditional weakness of polyamides, has been reduced to a minimum.

There are three individual offerings in the modified polyamide product series; each polyamide designed to meet a specific application requirement as presented below:

| A/G Series | Mechanical and structural parts |

| AE Series | For tribological applications |

| C Series | Electrical and electronic parts |

In electrical and electronic parts, this modified polyamide can be used in:

- Connectors

- Jacks

- Switches

- Power supply terminals

- Various cases

Automotive Applications - Engineering Plastic for Under the Hood Applications

The heat resistant modified polyamide 6T A/G and AE series are designed to meet specific mechanical, structural and tribological application requirements of under the hood parts including:

- Cooling system parts

- Cylinder head covers

- Thermostat cases

- Hydraulic system pistons

- Oil pump housings

Other mechanical and structural applications include light-load tribological application parts of office automation equipment.

Mitsui Chemicals recommends the following to mold this sophisticated engineering plastic for any application part:

Molding machine:

- The injection molding of this modified polyamide requires a molding machine having wear resistance (corrosion resistance for the flame-retardant grade).

- A small molding machine should be selected so that the volume of one shot will be not less than 10% of the maximum injection capacity.

- A standard nozzle should be used.

Mold:

- A steel material having wear resistance (corrosion resistance for the flame-retardant grade) is required for the construction material of a mold for ARLEN.

- An approximately 10-µ m vent is required.

Predrying:

- Any ARLEN resin that absorbs moisture after the bag is opened needs to be dried again.

- Dehumidifying dryer: 110°C x 2 to 6 hr.

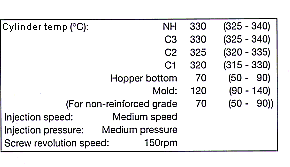

Electronic and Electric Standard Molding Conditions

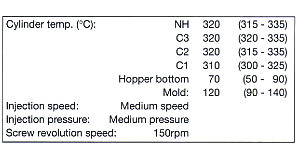

Mechanical and Structural Standard Molding Conditions