High Molecular Weight Polyethylene (HMWPE) for sound deadening of electronic office equipment and for sliding parts in automotive and electronic components.

LUBMER™

High Molecular Weight Polyethylene

Applications detail

Applications

Characteristics

- Introduction

LUBMER™ Pellet Type UHMWPE

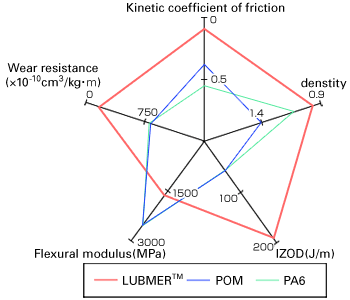

LUBMER™ is a unique self-lubricating polyethylene, a pellet type UHMWPE that can be injection molded. Developed with Mitsui Chemicals' original polymerization technology, LUBMER™ overcomes the processing limitations of traditional Ultra High Molecular Weight Polyethylene. In addition to its self-lubricating properties, LUBMER™ has high mechanical strength, low water absorption and high abrasion resistance compared to other specialty engineering resins like POM Acetal resin, or PA6 and PA66 nylon.

Halogen and PFOA Free Polymer

LUBMER™ is a halogen free polymer, and an effective replacement for PTFE as a PA6 or PA66 modifier that improves abrasion resistance. LUBMER™ features an extremely low coefficient of friction, resulting in a longer life span for lubricant free moving parts. Substituting LUBMER™ for PTFE offers an immediate solution for current health and safety concerns about perfluorooctanoic acid (PFOA). LUBMER™ is a PFOA free polymer.

Injection Moldable Resin

UHMWPE has traditionally delivered excellent mechanical properties, but with processing limitations. LUBMER™ can be injection molded, overcoming traditional processing limitations. LUBMER™ may be injection molded by itself, or as a compounded blend with engineering materials like PA6 or PA66.

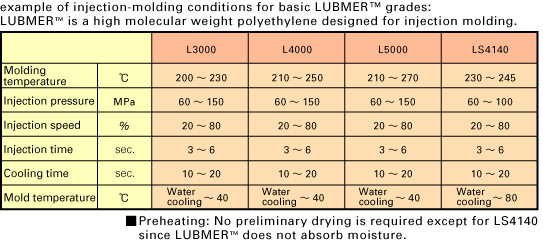

Processing

LUBMER™ is designed for general injection molding. See the chart below for suggested molding conditions