A transparent, heat resistant, 4-methylpentene-1 based polyolefin resin for release-films, LED molds, and for food and cosmetic packaging.

TPX™

Polymethylpentene (PMP)

Applications detail

Applications

Characteristics

- Introduction

- Characteristics

- Applications

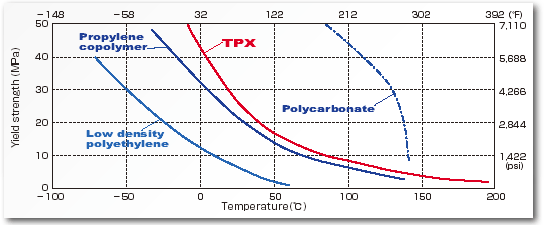

The TPX™ family of Polymethylpentene (PMP) polyolefin resins offer a unique combination of Transparency, Heat Resistance and Releasability. With low haze values, and low refractive index, TPX™ exhibits transparency equivalent to glass or acrylic. With a high melting point and extremely low water absorption rate, TPX™ is an excellent choice for items that require steam sterilization. Because the surface tension of TPX™ is very low, and the product displays excellent peeling characteristics, its Releasability properties are truly unique. Please download the TPX™ Physical Properties Table .

The very low density of TPX™ offers the potential for significant weight reduction of the final product. TPX™ can be injection molded, blow molded, or extruded into film, rods or sheets. TPX™ is manufactured only by Mitsui Chemicals, Inc. and is available in *pellet form.

TPX™ applications include:

- Animal Cages

- Cosmetic Caps and Tubes

- Heat Resistant Non-Woven Materials

- Labware

- LED Molds

- Mandrels and Sheaths for Rubber Hose Production

- Medical Devices

- Microwavable Food Containers

- Release Film

- Release Paper for Synthetic Leather

Food Containers

Food Containers

Animal Cages

Animal Cages

Release Paper

Release Paper

* Mitsui Chemicals America does not offer converted TPX™ rods or sheets.

For more information on TPX™ Film Opulent™ please click here.

TPX™ Polymethylpentene (PMP) Processing Method

- TPX™ is available in pellet form.

- Since TPX™ does not absorb water / moisture, it is not necessary to dry TPX™ before processing provided that it has been stored under normal conditions.

- Because of its high melting point TPX™ is normally processed at high temperatures in a range of ± 300°C. Molding equipment which can be set to such temperatures is therefore a basic requirement.

- To control / minimize the decomposition of TPX™, it is recommended to apply nitrogen-feeding at the hopper during molding process.

- Unlike PC, PMMA and other amorphous resins TPX™ is crystalline and therefore shows bigger mold shrinkage. Due to this fact, special attention has to be paid in case an existing mold which has been designed for any other resin, will be used for the processing of TPX™.

- Before starting to process TPX™, please be sure that no other resin is remaining in your machine. Particularly in the case of injection molding; even a small amount of foreign resin will result in an impair appearance of the product due to contamination. It is generally recommended to purge the equipment first with PP of low MFR and afterwards with TPX™.

Injection Molding

When TPX™ is in a melted state its viscosity declines drastically. Because of this, a pin gate is the most suitable gate for injection molding. This will help to minimize deformation and stress in the gate area. Particularly for shallow products, an off-center gate is highly recommended to avoid warpage. Injection molding of TPX™ is normally done within a range of 290°C and 310°C where 280°C and 320°C have to be regarded as lower and upper limits. For good controlling it is generally recommended to measure the actual resin temperature. Because of the very low viscosity of TPX™ at the melted state, it is also strongly recommended to inject at very low speed and very low pressure to minimize stress. The mold temperature is normally set within a range of 20°C and 60°C.

Extrusion

Because TPX™ needs a lot of energy to melt an extruder with an L/D ratio of at least 28, preferable 30 or 32, and with minimum 4 heating zones is strongly recommended. Also a special screw-design will allow you to easily process TPX™. If desired, we will help you to find the optimum screw-design for your machine. Sometimes a preheating of TPX™ pellets can be helpful.

Blow Molding

Because the viscosity of TPX™ declines sharply after it is melted, the blow molding of TPX™ is rather difficult and limited to the direct blow molding process. For the same reason the injection blow molding process does not work!

It should be noted that the transparency of blow molded TPX™-products is inferior to those made by injection molding.

Post-processing and Coloring

Because of its very low surface tension TPX™ has to be pre-treated with e.g. corona, flame, plasma, etc., for printing, painting or bonding it. Moreover, since TPX™ is low in mechanical strength, it is unsuitable for cutting manufacturing. TPX™ can be colored by dry blending and the most suitable way is to use a color masterbatch based on TPX™. However, please be sure to select pigments with high heat resistance, exceeding the molding temperature of TPX™.

Related Products

Heat Resistance

Peelability / Non-compatibility

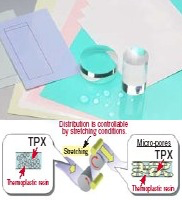

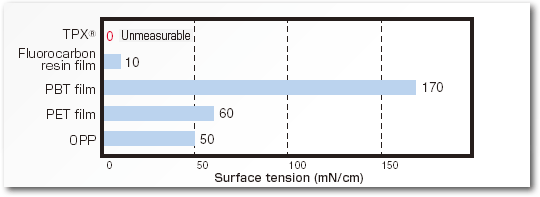

Since TPX™ has a very low surface tension of only 24mN/m, what is even lower than that of some fluorocarbons, TPX™ shows an excellent peelability from a big variety of materials. Because of this characteristic, TPX™ is used where an excellent separating property is required; for example as a release material at the time of curing thermosetting resins (such as urethane and epoxy). Furthermore, since TPX™ does not mix with other thermoplastic resins (such as PET and PP), it is used for the purpose of making PET and PP films micro-porous.

Separating Force from Epoxy

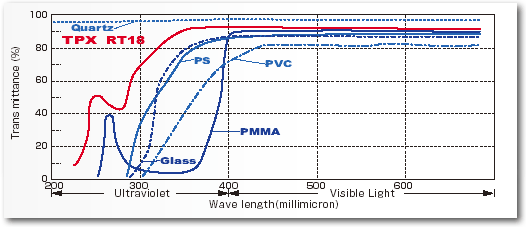

Transparency

Although TPX™ is a crystalline resin, it is transparent like glass and has an excellent transmission rate for visible light (> 93%; haze < 5%). On top of this it shows a better transmission in the UV-range compared with glass or other transparent resins. That is why TPX™ is, for example, used for spectroscopic analysis cells.

Low Refractive Index

The refractive index of TPX™ is only 1.463 n20D, which is lower than that of fluorocarbon or other transparent resins. So in the case where low-refraction material is required, TPX™ is one of the best choices.

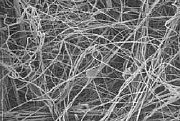

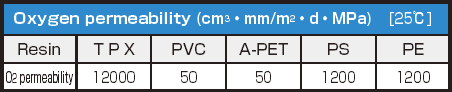

Gas Permeability

TPX™ has a very high gas permeability (10 times higher than that of PE), which makes it an excellent material for gas separating applications like permeable films, membranes and hollow fibres.

Low Density

TPX™ provides the lowest density (830kg/m3) among all thermoplastic resins; i.e. it offers the largest specific volume, which makes it possible to reduce molded-part weight by substituting other resins with TPX™.

Steam Resistance

The water absorption of TPX™ is very low and therefore dimensional change caused by hydrolysis cannot be observed. Even in boiling water, TPX™ does not hydrolyze. Therefore TPX™ is the predestined material for such applications which require steam sterilization.

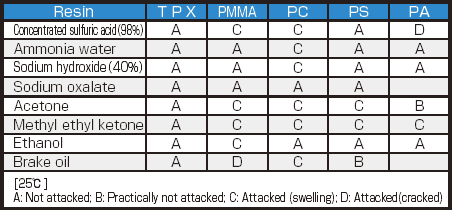

Chemical Resistance

Like polyolefins, TPX™ shows an excellent chemical resistance which is better than that of polycarbonate or acrylics. That is why TPX™, for example, is so often used in the cosmetic field for caps and tubes.

Low-dielectric Properties

Because of its outstanding dielectrical properties - ε = 2.1 and tan δ = 0.0008 (at 12 GHz) - TPX™ fits very well in the field of high-frequency applications.

Food Sanitation Properties

TPX™ is available in a wide range of grades to meet requirements and regulations of various domestic markets, US FDA-standards and EU-food-standards.

As for the EC Directive, it is necessary to check the conformity of the application at the level of the end product. TPX™ contains chemical substances whose Specific Migration Limit (SML) is 0.05 mg/kg and 5 mg. For the details of the conformity of TPX™ with the FDA regulations, please contact our responsible department.

Please click the table below to see the list of TPX™ Polymethylpentene (PMP) applications and grades.

TPX™ Polymethylpentene (PMP) Case Studies

Explore our case studies to learn more about the applications of TPX™

Food Containers

Heat Resistance | Releasability (Antifouling Property) | Transparency

TPX™ is widely used for food containers.

Benefits of using TPX™

One of the characteristics of TPX™ is its anti-fouling property. This is enabled by its releasability, which is higher than that of other resins. The material also features high heat resistance, which permits use in microwave ovens.

Recommended Grades

RT31/RT31XB/RT18/RT18XB

Release Film for FPC

Heat Resistance | Releasability Protrusion and Recess | Followability

TPX™ is used for molding FPC substrates and has widespread application for release films.

Benefits of using TPX™

While boasting high heat resistance, TPX™ also features low heat distortion temperature, which enables it to follow minute protrusions and recesses of FPC substrate surface. This stops adhesive leaking to the circuit section during the pressing process. TPX™ is also more releasable than other materials, simplifying releasing tasks.

Recommended Grades

RT18/MX002/MX004

Rubber Hoses

Heat Resistance|Releasability|Dimensional Stability|Repeated Use

TPX™ is applied widely for process materials for rubber hose manufacturing process (sheaths and mandrels).

Benefits of using TPX™

TPX™ features excellent heat resistance and enables high temperature vulcanization. TPX™ mandrels ensure high precision of the hose's inner diameter while TPX™ sheaths enable mirror finishing of the hose's exterior. Both mandrels and sheaths can be used repeatedly, enabling manufacturing costs to be lowered.

Recommended Grades D845/MX002/MX004/DX560M

Release Paper for Synthetic Leather

Heat Resistance|Releasability

The advantages of TPX™ enable it to be used for release paper for synthetic leather.

Benefits of using TPX™

Because of its high heat resistance and pattern transferability, TPX™ is used widely for release paper for synthetic leather. It can also be used more repeatedly than other materials, helping to reduce the process cost.

Recommended Grades

DX231|310/MX002

Experimental Apparatuses

Transparency | Chemical Resistance

The advantages of TPX™ enable it to be used for experimental apparatuses.

Benefits of using TPX™

Because of its stable C-C bonds, TPX™ has better chemical resistance compared with PC/ PMMA materials. TPX™ basically shows excellent chemical resistance, particularly against acids, alkalis, and alcohol. For this reason, TPX™ is also used for experimental apparatuses.

Recommended Grades

RT18/RT31/MX002O

Hollow Fiber

Gas Permeability | Steam Resistance

TPX™ is used for hollow fiber by taking advantage of its gas permeability. Benefits of using TPX™ TPX™ is characterized by its excellent gas permeability, which derives from its molecular structure. This gives TPX™ broad gas permeative applications, such as hollow fiber for artificial lungs and gas separation membranes for sewage treatment facilities.

Recommended Grades

DX818/DX470/MX004

Resin Modification

Releasability|Chemical Resistance

Given its characteristics, TPX™ is used as a resin modifier. Above all, its superior heat resistance and releasabiltiy enable it to be used for electronic materials and special printing paper.

Benefits of TPX™

When TPX ™ is added to another resin and then stretched, an even void is created between TPX ™ and the resin. This helps improve the printablity and optical properties.

Heat-Resistant Wraps

Heat Resistance|Transparency

Properties of TPX™ enables it to be used for wraps which are compatible with microwave ovens.

Benefits of TPX™

Wraps made by using TPX ™ remain unmelted at higher temperatures than conventional wraps (PVDC and PE wraps). Hence, they can be used safely for cooking or reheating food in a microwave oven.

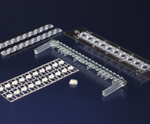

LED Mold

Heat Resistance|Releasability

The advantages of TPX™ mean it can be used for resin molds of LED.

Benefits of using TPX™

Harnessing its heat resistance and releasability, TPX™ is used for the release molds of LED. Moreover, these molds can be used repeatedly, helping to reduce manufacturing cost.

Recommended Grades

RT18

Animal Cage

Transparency|Steam Resistance|Light Weight

Advantages of TPX™also make it appropriate for animal cages.

Benefits of using TPX™

Taking advantage of its heat resistance, transparency and light weight, TPX ™ is used for animal cages. TPX ™ has been used in medical related applications signifying that the cages have a minimal impact on living things.

Recommended Grades

MX004/MX004XB

TPX™ Polymethylpentene (PMP) Precautions

1. General Precautions

- The data contained on this website are representative examples of actual measurement values recorded on the basis of our testing methods. The information contained herein are based on the information, data, etc. that are available at the moment. However, we do not provide any warranty as to the accuracy or suitability thereof for any particular applications.

- For detailed technical information, please contact us.

- For detailed safety information, please refer to the Materials Safety Data Sheet for TPX™.

- Please take care of industrial property rights with respect to the applications described in this website. Before using TPX™, please evaluate the practical applicability of TPX™ and check to be certain that there will be no problem in using it.

- Please avoid fire, direct sunshine, water wetting and any abrupt change in temperature in the place of storage of TPX™.

- Please avoid the outdoor use of TPX™ for a long period of time. Use of TPX™ for a long period may cause a change in color or a deterioration in quality.

These precautions are given on the assumption that TPX™ will be used in a normal way. If TPX™ is used in any special way, please take additional safety measures appropriate for such particular application or use.

2. Use of TPX™ for Medical-related applications and Food contact applications

Please contact us when you intend to use TPX™ for such applications