An antiblocking additive for film, and a superior alternative to erucamide or silica

MIPELON™ Masterbatch

Ultra-high Molecular Weight Polyethylene Fine Particles in a Masterbatch

Introducing a Polyolefin Alternative for Anti-block and Slip Additives

Applications detail

Applications

Characteristics

- Introduction

- Characteristics

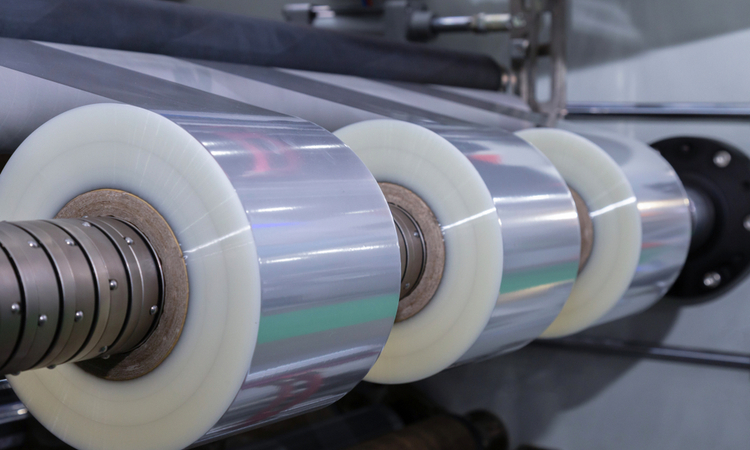

High-speed converting processes require rolled film to unwind easily and with minimal force. Blocking is the failure of the film to easily separate from itself and is most often seen in film with a large surface area and a smooth surface. To alleviate this problem, film producers create a micro-rough surface by adding finely milled inorganic slip agents like silica in low percentages into the polymer resin.

The challenge, however, is these inorganic additives are by their nature incompatible with the polymer matrix in the film, which risks non-uniform surface irregularities and the particles being ejected from the film surface during rigorous unwinding and converting operations.

MIPELON™ Masterbatch offers film producers and converters a new concept. MIPELON™ is a fine particle ultra-high molecular weight polyethylene and is more compatible than inorganic additives with either polyethylene or polypropylene resins in a film structure. The benefits of MIPELON™ are now available in an easy-to-handle masterbatch. Polyolefin films made with MIPELON™ Masterbatch can provide more uniform surface irregularities without particles falling off the surface, enabling more efficient converting operations.

In addition to blocking, film producers must also be concerned with slip, understood to be the friction between films and between film and converting equipment. Film producers often supplement the base polymer with slip additives to improve the film’s movement through extrusion lines and downstream packaging equipment. Primary unsaturated fatty acid amides such as erucamide are known to migrate quickly through polyolefin films and are commonly used as slip agents.

Controlling this migration is a major challenge, to avoid potential plate-out on the equipment and possible contamination of the packaged product. MIPELON™ Masterbatch is a polyolefin and is far more compatible with the polyolefin film matrix. By incorporating MIPELON™ Masterbatch into the film recipe, producers may be able to lower the loading level of slip agents like erucamide. Polyolefin films made with MIPELON™ Masterbatch can therefore enable more efficient converting operations and cleaner film.

MIPELON™ Masterbatch is available with three carrier resins:

> Low Density Polyethylene

> Homopolymer Polypropylene

> Random Copolymer Polypropylene

For additional information, or to speak with our experts, please click the Contact Form button below and let us know the best way to contact you!

MIPELON™ Masterbatch is made with fine powder particles of MIPELON™ dispersed in either Low Density Polyethylene, or Homopolymer Polypropylene, or Random Copolymer Polypropylene carrier resin. The high chemical stability of MIPELON™ ultra-high molecular weight polyethylene in aqueous, solvent, acidic and alkaline environments, as well as its very narrow particle size distribution offers film producers a superior alternative to inorganic antiblocking additives like silica.

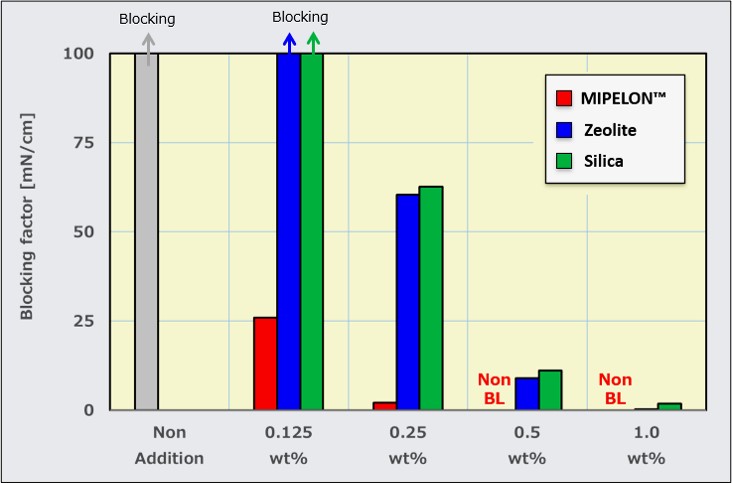

For experimental test purposes, a single layer Linear Low Density Polyethylene (LLDPE) 40-micron film was produced with varying weight percent loadings of MIPELON™, Zeolite and Silica additives. For this evaluation, MIPELON™ Masterbatch with Low Density Polyethylene carrier resin was added to LLDPE film resin. Test film of 200-millimeter width was evaluated for blocking at 200 millimeters per minute. MIPELON™ delivered superior antiblock performance at lower loading levels than either Zeolite or Silica as seen in the chart below:

The above data are representative values of experimental work and do not guarantee performance. All parties are strongly encouraged to develop their own test data and performance evaluation prior to commercial use of any product.

To learn more, or to discuss your specific requirements , please click the Contact Form button below and let us know the best way to contact you!