Lubricant for PVC, pigment dispersant, releasing agent for engineering plastics and toner

Hi-Wax™

Low molecular weight polyolefin

Applications detail

Applications

Characteristics

- Introduction

- Characteristics

- Applications

HI-WAX™ Polyethylene Wax

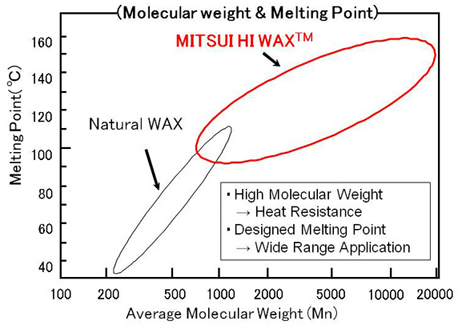

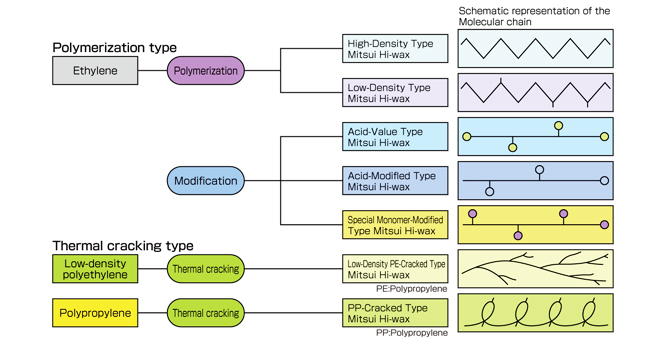

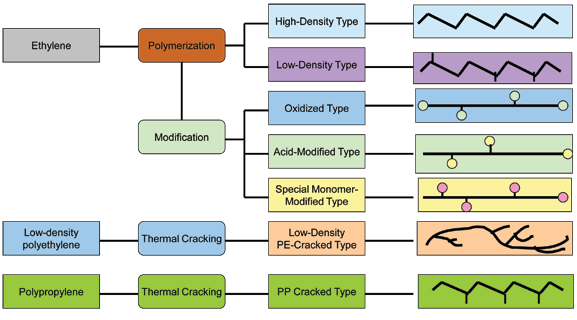

HI-WAX™ is a polyethylene wax with various grades in Polymerization type, Modified type and Thermally Cracking type. The wax can be used as a slip agent, disperant, resin modifier, and mold release agent due to its molecular structure, which enables it to outperform natural waxes.

The performance characteristics and properties of the synthetic wax, include:

- Solid or semisolid matter at room temperature

- Low melting point, melted at room temperature ~150°C

- Cystalline low molecular resin

- Molecular weight: 300 ~10,000 (low molecular)

Contact Us

MITSUI CHEMICALS AMERICA, INC.

TEL

+1 914-253-0777

FAX

+1 914-253-0790