Injection molded seal rings, bearings, and thrust washers for Automotive applications. Oil seals and impellers for Industrial applications. Wire extrusion coating, and matrices for carbon fiber composite structures for Aerospace applications.

AURUM™

Thermoplastic Polyimide

The Highest Class of Heat Resistance for a Thermoplastic Engineering Resin

Applications detail

Applications

Characteristics

- Introduction

- Characteristics

AURUM™ challenges the conventional wisdom that while polyimides offer exceptional high-heat performance, they are difficult to process. Unlike traditional thermosetting polyimide, from which parts are often machined from stock shapes or thin sheets, AURUM™ is a thermoplastic resin that can be injection molded into high precision parts.

The stiffness and stability of these parts in a high temperature environment are key requirements in many automotive, aerospace, and industrial applications. AURUM™ has a glass transition temperature (Tg) of 245oC which is 100oC higher than PEEK resin and exhibits a stable coefficient of thermal expansion at temperatures up to its Tg. AURUM™ has the highest glass transition temperature of any thermoplastic resin.

AURUM™ is a special type of thermoplastic polyimide, developed with Mitsui Chemical’s technology. Car manufacturers in the United States began using AURUM™ for thrust washers in the powertrain during the late nineties, and within ten years, oil rings made with AURUM™ could be found in heavy construction machinery.

Today AURUM™ finds use in the following key automotive applications:

> Bearings

> Transmission Seal Rings

> Transmission Thrust Washers

> Turbo Charger Abradable Seal

The high temperature resistance of AURUM™ Thermoplastic Polyimide has led to the development of high-performance industrial oil seals and impellers, and of demanding wire coating applications in the aerospace industry.

For additional information, or to speak with our experts, please click the Contact Form button below and let us know the best way to contact you!

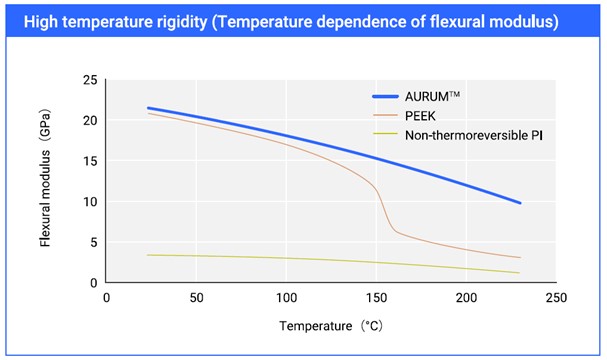

High Temperature Rigidity

AURUM™ has a high glass transition temperature (Tg) of 245℃ and exhibits excellent high temperature stiffness at over 150℃ compared to PEEK. Unlike traditional thermosetting polyimide, AURUM™ is a thermoplastic resin that can be fiber reinforced to improve initial strength.

The above data are representative values of experimental work and do not guarantee performance. All parties are strongly encouraged to develop their own test data and performance evaluation prior to commercial use of any product.

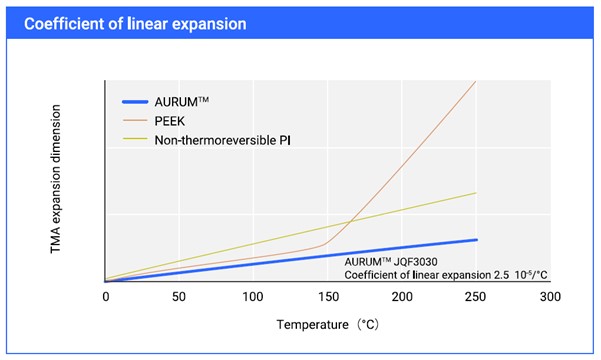

Coefficient of Linear Expansion

Thermoplastic resins can be modified with various fillers and additives to adjust the coefficient of expansion, making it possible to customize raw materials that meet both molding and application requirements. Because AURUM™ is a thermoplastic resin, its coefficient of expansion can be similarly adjusted.

As AURUM™ has the highest class of glass transition temperature of any thermoplastic resin, the coefficient of expansion is stable up to 245℃ and can be controlled at a level equivalent to aluminum.

The above data are representative values of experimental work and do not guarantee performance. All parties are strongly encouraged to develop their own test data and performance evaluation prior to commercial use of any product.

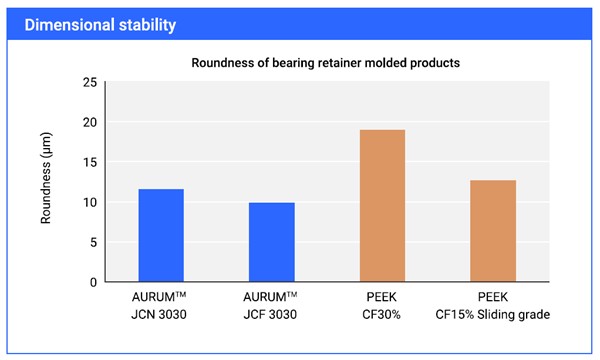

Dimensional Stability, Shrinkage Rate

AURUM™ demonstrates a shrinkage factor of 0.7% that is half that of PEEK, which ranges from 1.5% to 2.0% Parts molded from reinforced AURUM™ grades, demonstrate superior dimensional accuracy. Therefore, as AURUM™ provides excellent dimensional accuracy for molded products, post-molding processing may not be required even for the most demanding components.

The above data are representative values of experimental work and do not guarantee performance. All parties are strongly encouraged to develop their own test data and performance evaluation prior to commercial use of any product.

To learn more, or to discuss your specific requirements , please click the Contact Form button below and let us know the best way to contact you!